New environmentally friendly coatings with a very high air purification effect!

In an era where environmental concerns are at the forefront of global discussions, companies are increasingly recognizing the need to innovate sustainably. A group of experts in their field came together to develop new environmentally friendly coatings with a very high air purification effect in a project called “PhRischLuft”*.

*PhRischLuft” is a research project sponsored by the German Federal Ministry of Education and Research under the funding code 13XP5072A.

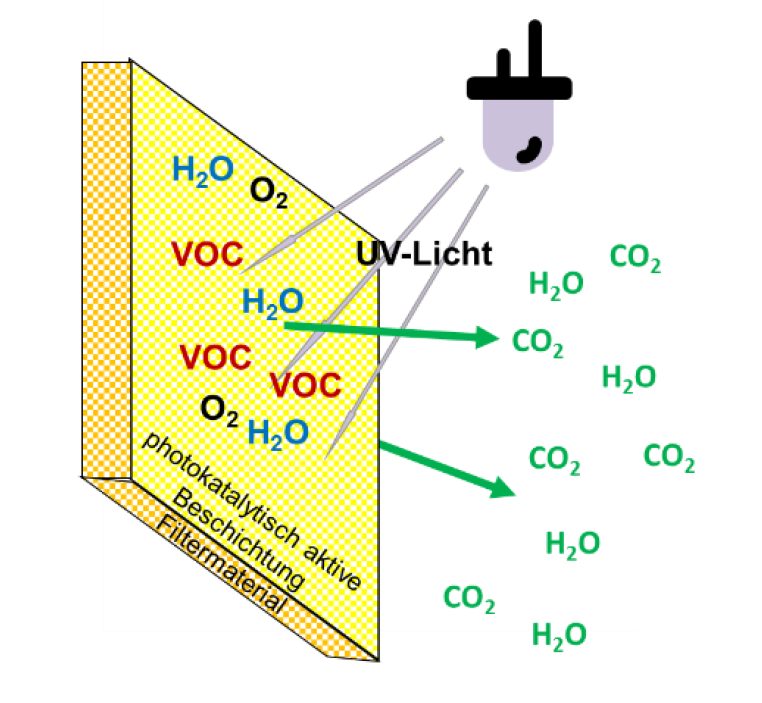

Schematic representation of how the PhRIsch-Luft coating works (source: all IPA)

The project partners EASYTEC GmbH, Fraunhofer IPA, Griwecolor GmbH, Keller Lufttechnik GmbH + Co KG, and TU Berlin worked together on this groundbreaking initiative. PhRischLuft is an innovative project to develop coatings that protect surfaces and actively contribute to air purification. The core of the project is the integration of TiO2 and UV LED technology. A combination that is known for its strong air purification capabilities.

In this joint project, experts from various fields worked together to research photocatalytically active coatings on filter materials for the chemical conversion of gaseous pollutants into harmless degradation products in ventilation systems. As a result of this project, new environmentally friendly coatings were developed that achieve a very high air purification effect due to their photocatalytic activity activated by UV LEDs.

The power of TiO2 Titanium Dioxide:

Titanium dioxide, a versatile compound used in various industries, is the key ingredient behind the PhRischLuft solution’s powerful air purification. When irradiated with special UV LED light, TiO2 creates a photocatalytic reaction that breaks down pollutants in the air. This ensures a continuous and effective air purification process.

The “PhRIschLuft” solution:

In the project “Photocatalytically active coatings on filter materials for air purification of polluted indoor spaces – PhRIschLuft”, new photocatalytically active coatings in combination with UV LED wavelengths were researched as a solution to this problem.

In contrast to filter mats such as activated carbon filters, which bind pollutants to their surface and become saturated after a certain time and have to be replaced, purification systems with photocatalytic air purification require significantly less maintenance. The filter mats convert the pollutants into harmless gaseous degradation products and therefore do not become saturated.

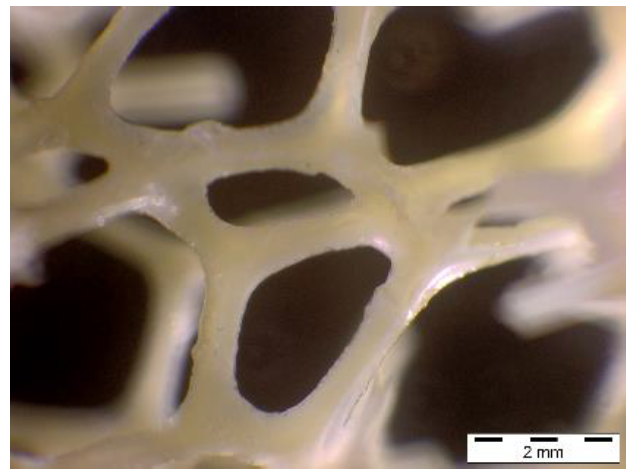

In the “PhRIschLuft” research project, formulations for aqueous coating systems were developed and the coating materials were applied to filter mats. The properties of the coating materials were adjusted in such a way that Griwecolor was able to produce homogeneous coatings on the filter mats.

Microscope image of a filter mat coated with a photocatalytically active coating (source: IPA)

The coatings developed in this project were tested at Fraunhofer IPA for their suitability in principle for the application. The photocatalytic activity of the coatings was examined as an initial exclusion criterion for possible candidates. For this purpose, the photocatalytic NO degradation of the samples was examined in a flow reactor in accordance with ISO 22197-1.

The oxidation of NO to NO2 in the presence of the photocatalytic coating is quantitatively recorded, which provides information on the efficiency of the pollutant degradation of the coating. Initial approaches already showed a high activity of more than 50% NO degradation. In the course of the project, the activity was increased to a very high degradation rate of almost 100% in the test setup.

In addition to NO degradation, which provided initial information on photocatalytic activity, the degradation performance of other model pollutants was investigated at TU Berlin and Fraunhofer IPA in various test setups. A degradation performance for various VOCs (e.g. isopropanol, toluene) was found.

In addition to photocatalytic activity, mechanical stability is an important factor for the practical use of the new coatings. Crushing tests were carried out for this purpose. Microscopic examinations of the coated filter mats after mechanical squeezing with a metal roller showed that the coatings had sufficient adhesion to the filter mats in a dry state before and after UV exposure for the application. The filter mats can therefore be handled without any problems during installation, removal or maintenance work when dry. Additional tests on the formation of particles after long-term UV exposure showed that no particles of concern are released from the coating.

Verification of the function of the ventilation system modules in demonstrators

Demonstrators for ventilation system modules were designed and constructed by Keller Lufttechnik to test their suitability for practical use. The coating is activated using UV LED panels designed and developed by EASYTEC GmbH. These UV LED panels are used to activate the coated filter mats in the airflow of the demonstrator modules. In the demonstrators, the PhRIschLuft coatings were tested for their performance in the application. To this end, tests were carried out with various parameters. The parameters dwell time, exposure intensity, wavelength of the UV source, and pollutant concentration were varied to optimize them for the highest possible degradation performance.

After optimization of the parameters, a very high air purification effect with over 90% pollutant degradation was demonstrated using model pollutants. With 300 ppm isopropanol and a dwell time of 1.03 s, a degradation efficiency of 95% at 20% UV intensity was achieved.

Field trials:

The high degradation performance was confirmed in field trials. The field tests were carried out at the TU Berlin. In a storage room contaminated with VOCs (72 m3), the degradation of benzene, chlorobenzene, toluene, xylene, and styrene was quantitatively verified using gas chromatography. At 10% UV intensity and a volume flow of 130 m3/h, a degradation rate of between 98 and 99% was determined for xylene and chlorobenzene. The toluene concentration was reduced by 75% during the operation of the demonstrator.

In another field test, the demonstrator module was used during the coating of a hall floor (400 m2) with a 2K epoxy floor coating.

The floor was coated with two layers of the floor coating on two consecutive days. On the first day, the emission was measured without the PhRIschluft demonstrator module and on the following day using the demonstrator module.

With a volume flow of 130 m3/h and 10% UV intensity, the air purification system was able to reduce the VOC concentration of the approx. 12,000 m3 hall by up to 80% by using the new technology.

PhRischLuft in the application

New multifunctional and energy-efficient ceiling panel with integrated air purification!

EASYTEC has integrated the principle of photocatalytic air purification into 2 different systems.

- a system with UVA LED radiation and the new photocatalysis for air purification and simultaneous air disinfection.

- a system with UVC LED radiation for air and surface sterilisation

Air Disinfection with UVC LED

The new “EASY-AVACS” multifunctional ceiling panel sterilizes room air safely, reliably and without chemicals. The new technology sterilizes the air 5 times per hour with a sterilization rate of over 99.9%, with maximum efficiency and minimum energy consumption.

Air purification with UVA LED and TiO2

The air purification systems use energy-efficient UVA wavelengths to deactivate dangerous coronaviruses and eliminate other dangerous bacteria, fungi and harmful organic compounds in the air to create a healthy atmosphere in every room.

Conclusion

EASYTEC’s participation in the “PhRischLuft” project is an important milestone on the company’s path to developing further innovative, environmentally friendly solutions. By utilizing the properties of titanium dioxide and UVA LED technology, EASYTEC is not only revolutionizing the coatings industry, but also contributing to a cleaner and healthier future for us all. As the project progresses, we anticipate the positive impact these breakthrough coatings will have on air quality and environmental sustainability.

If you would like to know more about the project or the new air purification systems, please feel free to contact our experts!